I have presented and reviewed my Tomix 6425 model around two months ago. I knew already back then I would be converting it to DCC. So my next step was finding a fitting decoder and placing an order. As soon as I had it, I could start the work.

The decoder I picked was ESU LokPilot Nano. I do not know of anyone else using this particular product with the Tomix cleaning car, and the main reason I went for this choice was its size. LokPilot Nano is supposed to be the smallest DCC decoder available on the market.

It is indeed tiny and measures roughly 7 x 8 mm. There's just no way it won't fit.

The decoder comes with attached cables and a small PCB connector at the end. That is much more than I need and I will be reducing the provided wiring.

I only need six cables:

- track signal input (2 wires)

- motor output (2 wires)

- strobe light output (2 wires)

I also took the opportunity and inspected the voltages on the input and on the motor output of the decoder. I was always curious what those looked liked. So here they are. This is the DCC signal straight out of my Roco z21 system as seen on my oscilloscope.

And below is the motor output. Personally I think that is very interesting. There are reports all over the Internet of the Tomix cleaning car dying very quickly on DCC layouts. Looking at the difference between the pre and post decoder signal plots, it is really not a surprise. The characteristics of those two are completely different and the DCC voltage is actually higher. No wonder it could destroy an unprepared engine.

It's time to start the installation. Opening the car required one screw to be removed. The screw appeared to be holding just one of the bogies but in fact it was keeping the entire model together. Once the wheel-set was loose, the top cover also fell off.

There's an empty area in the metal ballast part. Everyone put their decoders there. The LokPilot Nano electronics fit inside this spot very easily. I was even able to add a layer of an insulation tape on the weight's surface and there was still a lot of space left.

There were several ways I could go about the electrical connections. I decided to re-use the existing PCB part and removed all the elements from its surface. Now I had just an empty board.

I also used a hobby multi-tool to create a gap in the PCB. This should allow me to pass the wires from the decoder without any hassle.

The required cabling was soldered to the board. 2 wires will pick up the voltage from the track and 2 other wires will deliver the power to the motor.

The remaining 2 wires are decoder's AUX output. I'm going to assign those to function F1 and use them to drive an orange strobe LED. This will create a "warning light" informing of the cleaning car's operation on the track.

Alright, time to close the model. It looks perfect in the photo below and I'm happy with the outcome BUT it is a completely different story on the inside. I did a stupid mistake and because of that sealing the car was a huge pain. I'm not going to go into details but my advice is - always check everything not just 2 times, but 10 times or more before you CUT anything.

I obviously need to add something around the strobe LED to fill the gap. I will be probably 3D printing a small ring element.

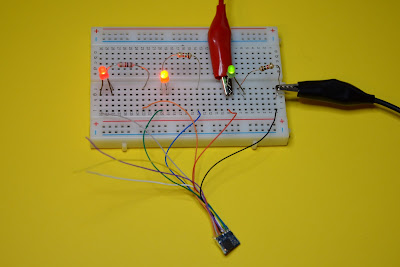

OK, so here's a demo. It actually works!

Two more cents about the DCC configuration. I had a strong feeling the cleaning engine was getting too much power at a full DCC throttle. It sounded as if it was going to fly away. I was afraid it would get damaged so I decided to reduce its maximum power.

On the LokPilot Nano decoder this can be achieved by modifying CV5. This register controls the top motor speed and offers a range of values from 0 to 64. After some experimenting I configured my unit to use the value of 13 as the maximum. This way the disc rotates very fast (definitely fast enough for the cleaning operation) and the produced motor noise still sounds "healthy" to me.

Full success. I can now use my Tomix car without switching between the DC and DCC controllers.

Nice guide, I used it to do mine and it was great.

ReplyDeleteI think I know what you cut by mistake as I've done the same thing to mine! Silly me removed the part to screw the bogie into while removing the switch.

I'm gluing some small nuts in to screw into instead.

Reading your procedure I decided to convert my two Tomix N-Scale cleaners. They have never been tried out and my knowledge lever is slightly above new-bee. i went online to purchase the ESU Lokpilot Nano decoders but found a variety of choices. Which one is the right one???

ReplyDeleteA Digitrax DZ126 fits easily in the space at the rear of the weight. After removing the components on the board I cut a small rectangular area out similar to what Tomasz did. Hope this helps.

Deletevery interesting, thank you! one question: the blinking led require and CV configuration? thank you!

ReplyDelete